在我们传统的加工工艺中,不锈钢焊接通常采用氩弧焊机进行加工,但是氩弧焊机存在着许多缺陷,而且在外观上也不够美观。采用手持式激光焊接机,能弥补缺陷,焊点美观,不变形。

In our traditional processing technology, stainless steel welding is usually processed using argon arc welding machines, but argon arc welding machines have many defects and are not aesthetically pleasing in appearance. Adopting a handheld laser welding machine, it can compensate for defects, with beautiful welding points and no deformation.

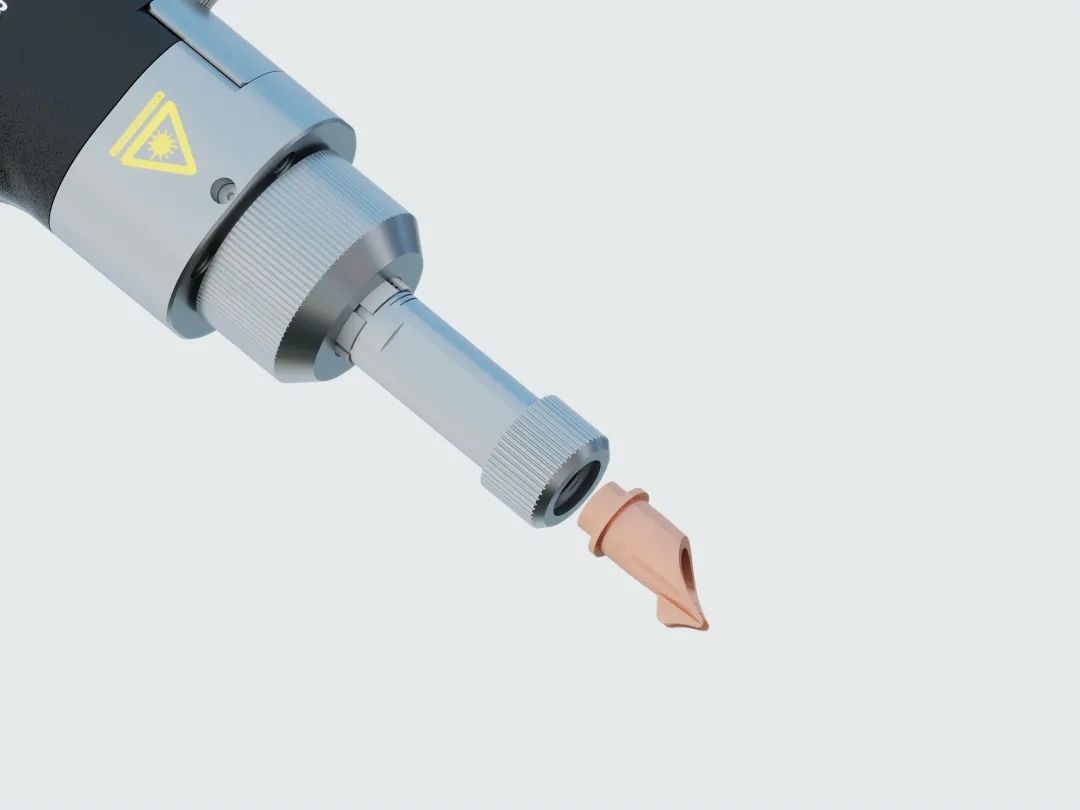

手持焊接激光机的焊接原理是将高能激光束耦合到光纤中,通过准直镜准直地平行光,然后聚焦到工件上进行焊接的激光焊接设备。对于难以焊接的部位,采用柔性传感非接触焊接,具有更大的灵活性。用户在操作本设备的同时,还可以实现对任意位置的点焊、直缝焊、重叠焊、圆周焊和氩弧焊。

The welding principle of a handheld welding laser machine is to couple a high-energy laser beam into a fiber optic, collimate the horizontal light through a collimating mirror, and then focus on a laser welding equipment on the workpiece for welding. For areas that are difficult to weld, flexible sensing non-contact welding is used to provide greater flexibility. Users can also perform spot welding, straight seam welding, overlap welding, circumferential welding, and argon arc welding at any position while operating this device.

所以,采用不锈钢焊接的手持激光焊接机有什么优点?

So, what are the advantages of using a handheld laser welding machine with stainless steel welding?

采用手持激光焊接设备,就可大大减少焊接的前期工件准备和对焊工的技术要求,对于焊接不锈钢制品的企业,只需根据不锈钢制品的厚度调整焊接参数,即可进行焊接,焊接过程中不需添加焊丝和其他辅助耗材。

By using handheld laser welding equipment, the preparation of workpieces and the technical requirements for welders in the early stage of welding can be greatly reduced. For enterprises welding stainless steel products, they only need to adjust the welding parameters based on the thickness of the stainless steel products to carry out welding, and there is no need to add welding wires and other auxiliary consumables during the welding process.

手持式激光焊接机具有穿透力强、焊接外观整齐美观、焊接牢固等特点。用于不锈钢门窗、扶手及不锈钢加工制品焊接,激光功率要求低,焊接容易。

The handheld laser welding machine has the characteristics of strong penetration, neat and beautiful welding appearance, and firm welding. Used for welding stainless steel doors and windows, handrails, and stainless steel processing products, with low laser power requirements and easy welding.

手持激光焊机的手持焊头采用5米进口光纤,可实现室外焊接,灵活方便。手持焊枪操作方式,可对工件进行任意位置、任意角度的焊接。两路智能切换,分时分光能量均匀分布。适合各类复杂焊缝,各种器件的点焊。易于实现自动化,可与机械手有机结合,使焊接更加灵活方便。

The handheld welding head of the handheld laser welding machine adopts 5-meter imported optical fiber, which can achieve outdoor welding and is flexible and convenient. The handheld welding gun operation mode allows for welding of the workpiece at any position and angle. Intelligent switching between two channels, with evenly distributed time division light energy. Suitable for spot welding of various complex welds and devices. Easy to achieve automation, can be organically combined with robotic arms, making welding more flexible and convenient.

手持激光焊接机可广泛应用于橱柜厨卫、楼梯电梯、货架、烤炉、不锈钢门窗护栏、配电箱、不锈钢家居,行业广告,灯饰和板金机箱机等行业复杂不规则的焊接工序。

Handheld laser welding machines can be widely used in complex and irregular welding processes in industries such as cabinets, kitchens, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel homes, industry advertisements, lighting, and sheet metal chassis machines.